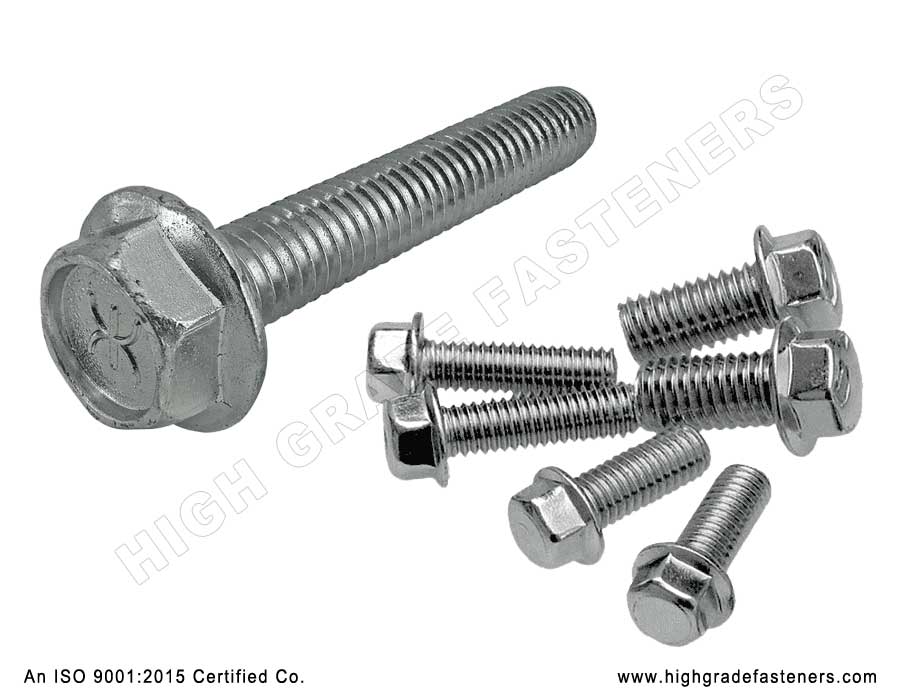

Flange bolts got their name due to the circular flange which is engineered right under its head. These flanges distribute the load evenly between the different joints of the structure which is being fastened by it but remember to fasten all the joints using the same dimension of flange bolt. These ensure that the structure being built is impeccably designed for maximum load-bearing capacity. Like we mentioned before, these bolts are used for high strength applications. But if that is combined with the characteristics of stainless steel, then you get one of the most potent fasteners for extreme applications.

It is available in stainless steel, carbon steel, and alloy steel to bear more wear and tear while also making it more corrosion resistant. It can also be purchased in bulk, making it a cost-effective solution for every need.

DIN 6921

Metric: DIN 6921

Inches: As Per Requirement

Flange nuts from us possess a few of the defining attributes of a washer. They are used to spread the load evenly to avoid uneven fastening surface of the operations. They also ensure that the fasteners are in place without moving about loosely. These wide flange nuts can be used as a replacement to the nut and washer combination. Therefore, these nuts are a cost-effective and quality substitute for nuts and washers if your project is a large scale one.

Flange weld nut come in varying sizes to allow its use with several bolts, each with different dimensional standards. Another advantage of these nuts is that they prevent the loosening of machining and electrical components while still allowing the free parts to move freely. Striking the perfect balance, in this case, has to be done with careful calibrations. It is available in stainless steel, carbon steel, and alloy steel to bear more wear and tear while also making it more corrosion resistant.

JIS B1190, DIN 6923

Metric: M4 to M16